Creating new potential for a future

with new possibilities for aluminum

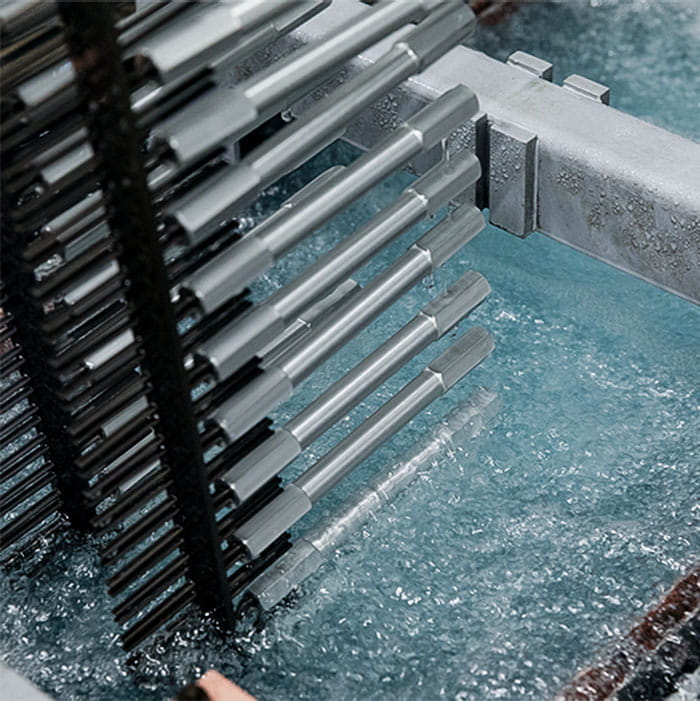

For a wide range of abrasion and corrosion issues of aluminum and the need for improvements in hardness and lubricating properties, we have offered solutions with our surface treatment technology as a manufacturer specialized in anodizing. Based on expertise cultivated for more than 40 years, we realize customers' ideals with cutting-edge technologies and optimum methods.

Our Five Strengths

Offering the world's

only technology

Manufacture of Kashima Coat🄬 for a lubricated anodizing

Handling materials

that are difficult

to anodize

Anodizing of aluminum die-cast materials

Leading the industry

Producing

hard anodized

coating as standard

Achieving annual production of over 100 million products Stable production system and anodizing capacity

Handling production processes from prototyping and small lot to mass production Adaptable to different types of order lots and masking methods

Kashima Coat

Optimal for sliding parts

Lubricated hard anodizing

offering superior abrasion resistance

MD Process

Protecting products from corrosion

Corrosion-resistant anodizing

for aluminum die-cast materials

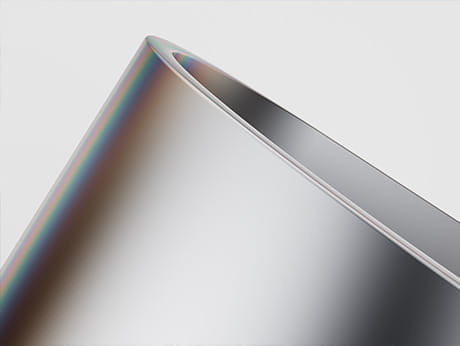

Oxalic Acid Anodizing

Keeps the surface roughness unchanged after treatment

Achieves superior heat resistance, corrosion resistance,

and a beautiful surface treatment

Introducing the unique technology that we acquired

through the accumulation of successes as a result of the persistent efforts to overcome challenges