Miyaki’s standard anodizing HARD ANODIZED

Hard anodizing forms a harder film than general soft and ordinary anodizing.

With enhanced durability, the robust film protects products even in harsh environments.

Hard anodizing forms a harder film than general soft and ordinary anodizing.

With enhanced durability, the robust film protects products even in harsh environments.

We have handled so many functional components requiring aluminum with hardness and wear resistance since our founding, so we accumulated expertise in hard anodizing, which became our strongest area.

At present, manufacturing hard anodizing is our most standard process.

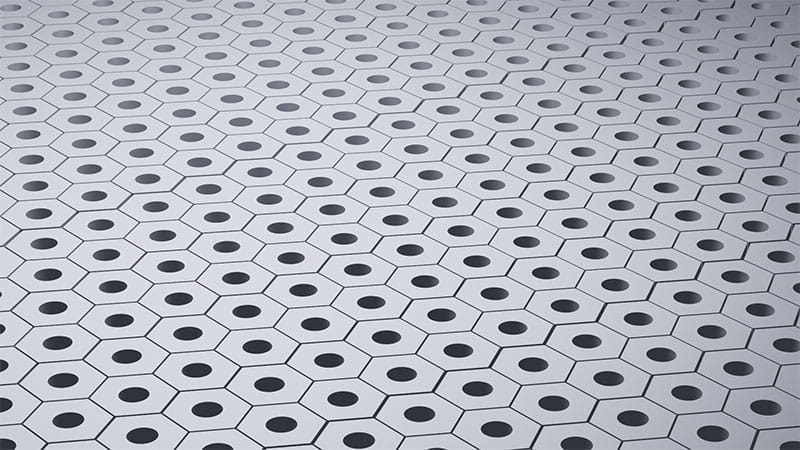

Thin pore walls and large number of pores Low hardness but superior stainability

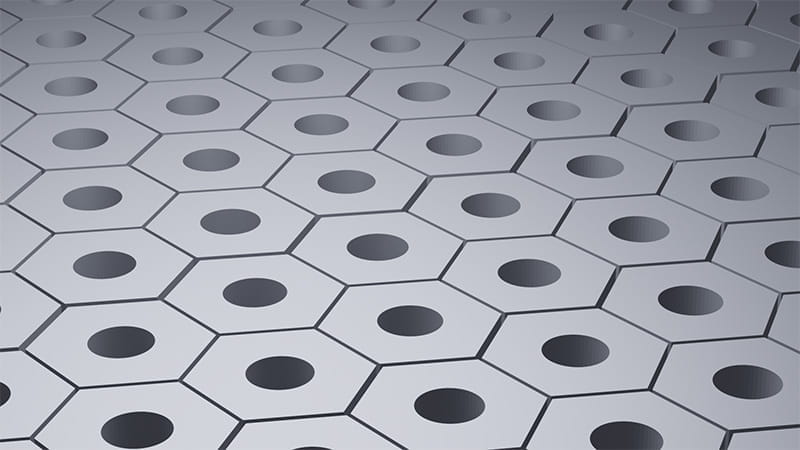

Thick pore walls and smaller number of pores Lower stainability but superior hardness and high wear resistance

| Ordinary and soft anodized coating | Hard anodized coating | |

|---|---|---|

| Color tone | Although it is normally white, it can be dyed in arbitrary color | Duralumin-based (2000 series and 7000 series): Light yellow Magnesium-based (5000 series and 6000 series): Grey |

| Hardness | 200 to 300 HV Aluminum < Ordinary anodized coating < Iron |

350 to 450 HV ※Varies depending on the material Iron (non-heat treated) < Hard anodized coating |

| Dimension | A half of the coating thickness is added to material dimensions | A half of the coating thickness is added to material dimensions |

| Major application | Architectural materials, industrial products, and decorative parts | Sliding parts, transportation equipment components, industrial equipment components |

Contact us for a quote or inquiry.