Achieving superior corrosion resistance that can even withstand seawater

High corrosion resistant anodized coating

for aluminum die-cast materials (ADC12)

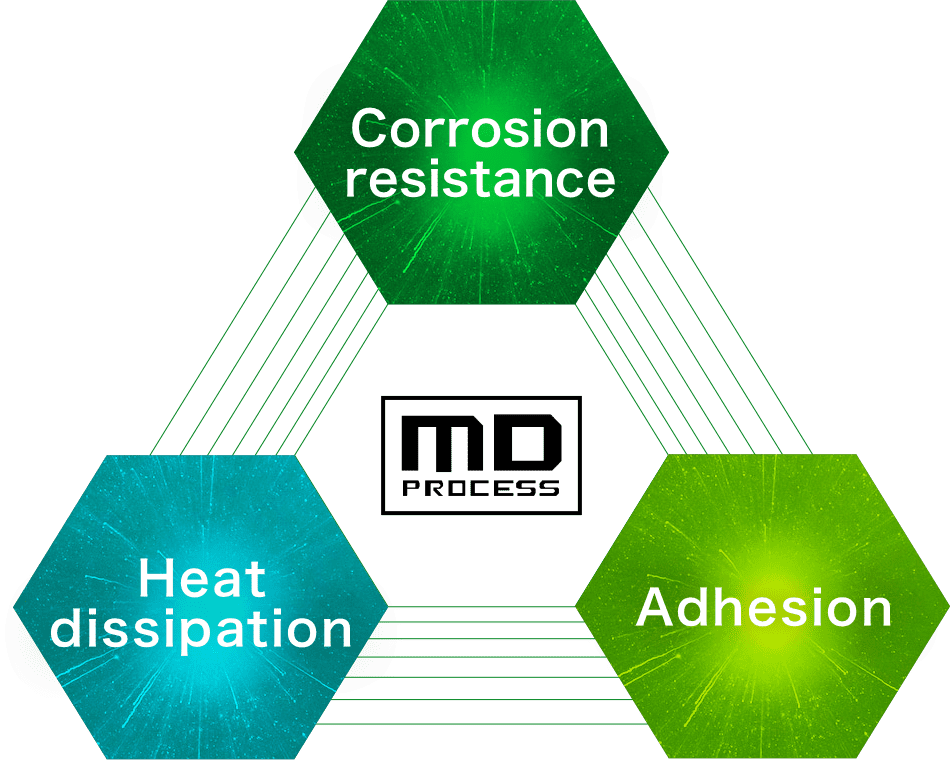

MD PROCESSMIYAKI die-cast process

Achieving superior corrosion resistance that can even withstand seawater

High corrosion resistant anodized coating

for aluminum die-cast materials (ADC12)

MD PROCESSMIYAKI die-cast process

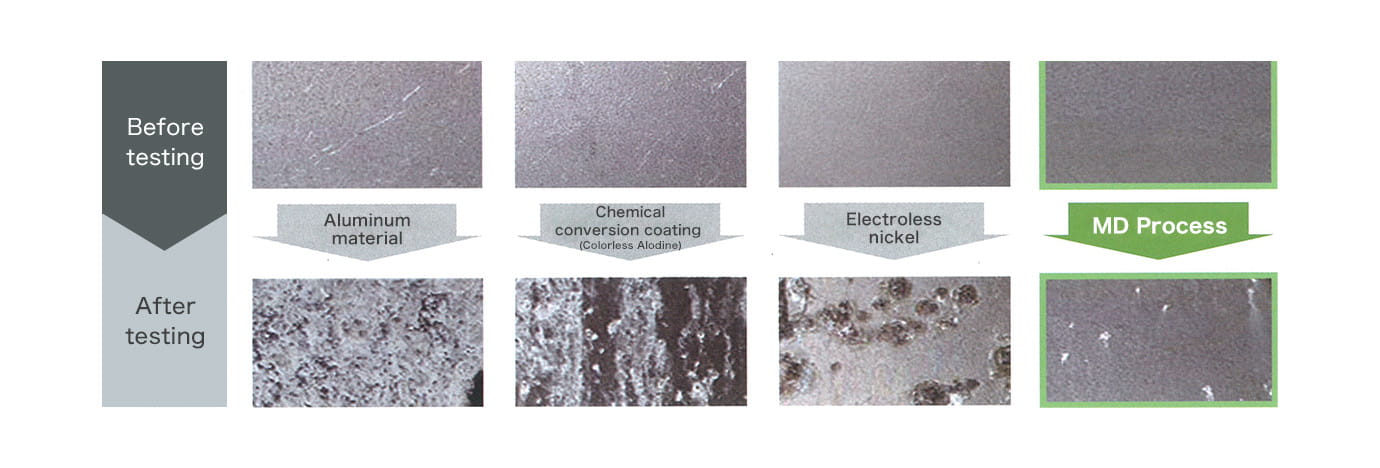

Because of the influence of added elements, such as silicon (Si), copper (Cu), and iron (Fe), aluminum die-cast materials have significantly low corrosion resistance and require surface treatment. Generally, even if aluminum die-cast materials are anodized, cells are not formed sufficiently, and adequate corrosion resistance is not achieved. Therefore, we developed the MD Process (Miyaki Die-Casting Process), which enables anodizing film formation even on materials that are hard to anodize and that provide adequate corrosion resistance through our original process suitable for aluminum die-cast materials. By selecting the optimum method, the MD Process forms high-quality anodizing film and provides adequate corrosion resistance even to aluminum die-cast materials.

TIPS

MD Process is high corrosion resistant anodizing developed by Miyaki Co., Ltd., for aluminum die-cast materials. Miyaki's original process enables the provision of adequate corrosion resistance to aluminum die-cast materials that are considered difficult to anodize by utilizing the optimum method and four key factors.

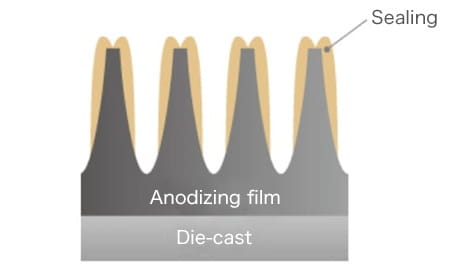

Anodizing film is not formed uniformly.

Sealing produces less effect = Poor corrosion resistance

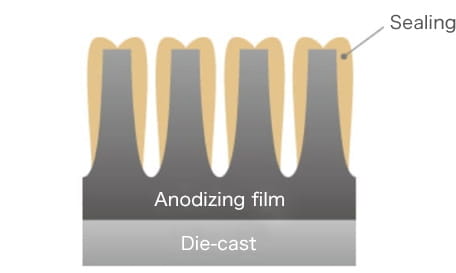

Anodizing film can be formed uniformly.

Sealing produces effect = Superior corrosion resistance

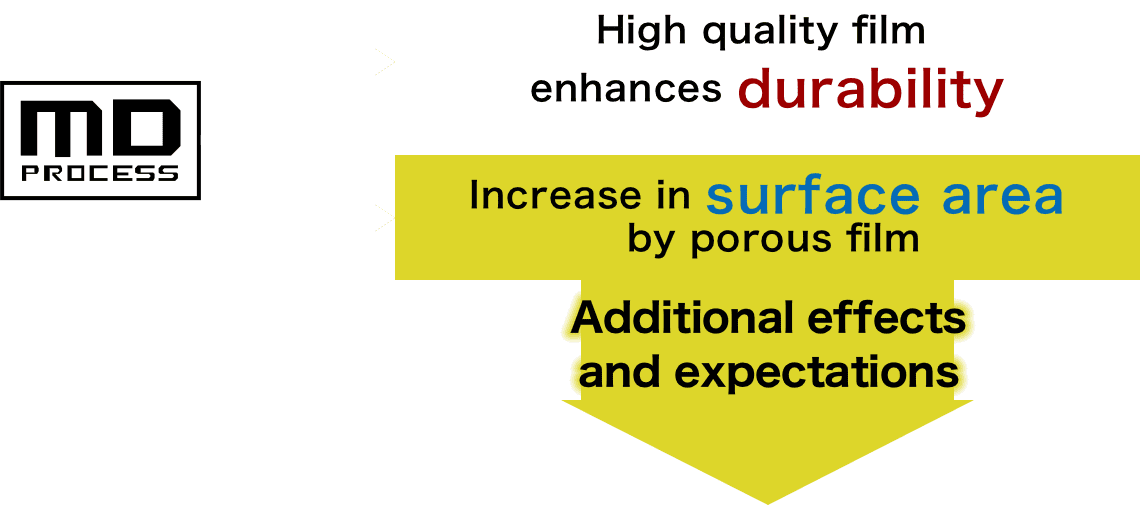

POINT High durability is achieved

Increased

surface area=Increased anchoring effect of painting

Applying the MD process increases surface area.

It produces the anchoring effect that it enhances painting adhesion, resulting in enhancement of corrosion resistance.

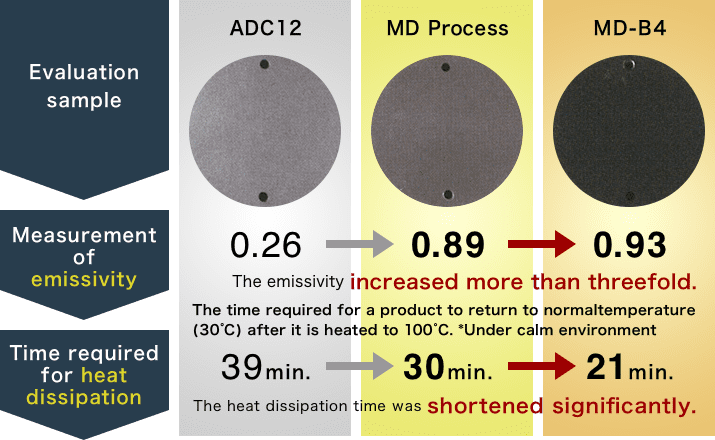

Increased emissivity and efficient heat dissipation

Blackening the color tone increases the effect. *The effect produced varies depending on the material shape and usage environment.

Contact us for a quote or inquiry.