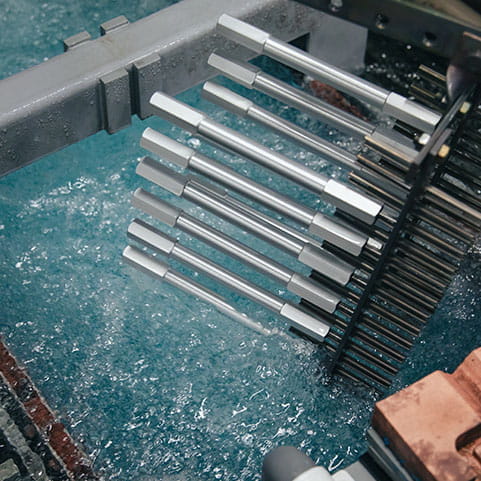

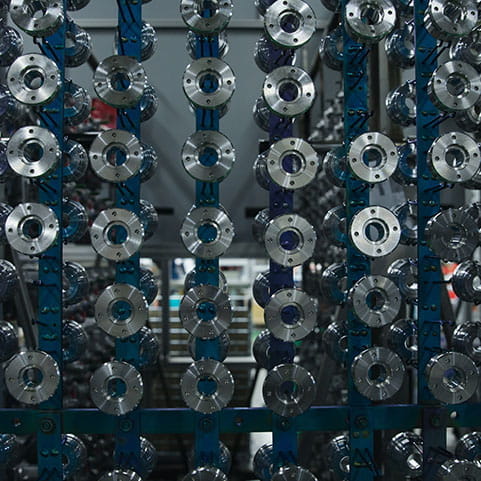

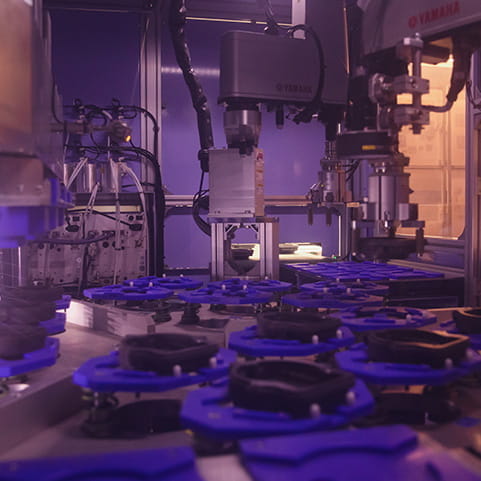

Production facilities including fully automated lines

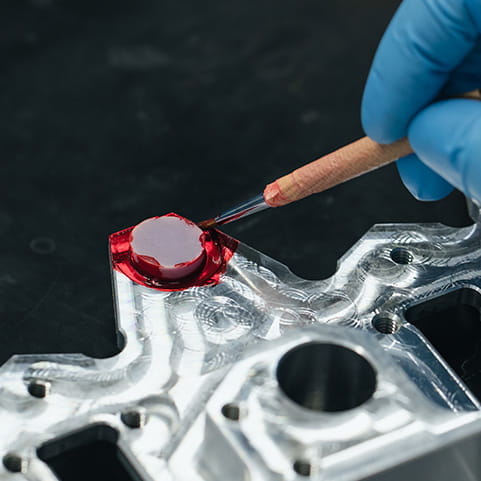

Since its founding, Miyaki has worked on the improvement of facilities to which customers can entrust production, including automated lines that realize stable production.

We constantly inspect and introduce not only anodizing facilities but also various types of measuring equipment and labor-saving equipment.

In addition, Miyaki is also making proactive efforts to improve the working environment.

With the spirit of creating good quality from good environment, we are focusing on the creation of an environment where our employees can work with a sense of security and safety.