Transforming Aluminum Die Cast Parts into Functional Parts

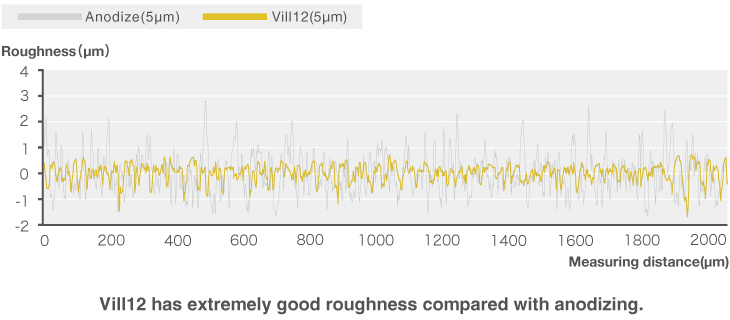

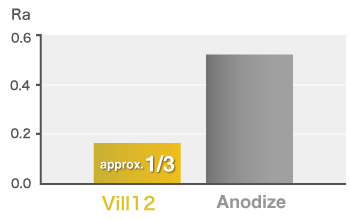

With standard anodizing, the surface of machined and cut parts becomes rough due to anodizing treatment. However, with Vill12, implementation of a completely different treatment process generates a film structure with a roughness close to that of the pretreated surface.

Salt Spray Test (120 hours)

JIS1994 Value (Ra)

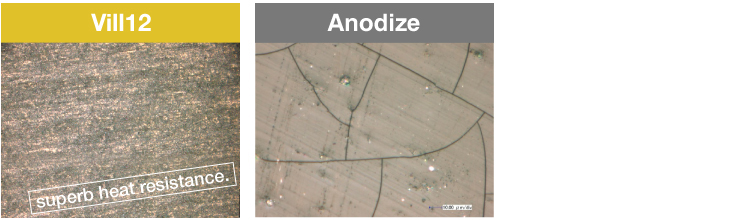

The film structure of Vill12 is overwhelmingly crack resistant in comparison to standard hard anodizing.

1 hour @ 400℃

Virtually no cracks were seen after 1 hour of thermal treatment at 400℃ due to superb heat resistance.

| Material | Film Thickness (μm) | Standard Hardness | Film Characteristics | Remarks | |||

|---|---|---|---|---|---|---|---|

| Recommended | Limit | (HV) | Hardness | Generation Capabilities | Corrosion Resistance | ||

| AC2A・B | 3 | 5 | 200 | ◯ | △ | ◎ | The material’s surface is rough, and surface cavities are visible after anodizing treatment. |

| AC4C | 10 | 30 | 450 | ◎ | ◯ | ◎ | Good film forming properties and surface roughness compared to other minerals. |

| AC7A・B | 3 | 30 | 450 | ◎ | ◯ | ◎ | Relatively good film compared to other minerals. |

| AC8A | 3 | 5 | 250 | ◯ | △ | ◎ | Superb strength and wear resistance makes it the perfect material for engine pistons. (good anodizing properties) |

| ADC6 | 10 | 30 | 450 | ◎ | ◯ | ◎ | Good film generation compared with other die cast treatments. |

| ADC12 | 3 | 5 | 250 | ◯ | △ | ◎ | Effect of additional element hinders thick film. Silicon and release agent easily left behind, causing excessive color variations. |

| Material | Film Thickness (μm) | |

|---|---|---|

| Recommended | Limit | |

| AC2A・B | 3 | 5 |

| AC4C | 10 | 30 |

| AC7A・B | 3 | 30 |

| AC8A | 3 | 5 |

| ADC6 | 10 | 30 |

| ADC12 | 3 | 5 |

| Material | Standard Hardness |

|---|---|

| (HV) | |

| AC2A・B | 200 |

| AC4C | 450 |

| AC7A・B | 450 |

| AC8A | 250 |

| ADC6 | 450 |

| ADC12 | 250 |

| Material | Film Characteristics | |

|---|---|---|

| Hardness | Generation Capabilities | |

| AC2A・B | ◯ | △ |

| AC4C | ◎ | ◯ |

| AC7A・B | ◎ | ◯ |

| AC8A | ◯ | △ |

| ADC6 | ◎ | ◯ |

| ADC12 | ◯ | △ |

| Material | Film Characteristics |

|---|---|

| Corrosion Resistance | |

| AC2A・B | ◎ |

| AC4C | ◎ |

| AC7A・B | ◎ |

| AC8A | ◎ |

| ADC6 | ◎ |

| ADC12 | ◎ |

| Material | Remarks |

|---|---|

| AC2A・B | The material’s surface is rough, and surface cavities are visible after anodizing treatment. |

| AC4C | Good film forming properties and surface roughness compared to other minerals. |

| AC7A・B | Relatively good film compared to other minerals. |

| AC8A | Superb strength and wear resistance makes it the perfect material for engine pistons. (good anodizing properties) |

| ADC6 | Good film generation compared with other die cast treatments. |

| ADC12 | Effect of additional element hinders thick film. Silicon and release agent easily left behind, causing excessive color variations. |